The problem most consumers face when purchasing suspension upgrade components for their vehicle is often whether or not they are purchasing the right product and will it live up to their performance expectations. Oftentimes, faced with cost and brand considerations, consumers may inadvertently purchase a product from a source that they think is a quality supplier/manufacturer, only to find out that the part they purchased for their American pony car lacked proper engineering and performance/safety validation, was built with substandard materials and with inferior quality processes. As a result, the "deal" they thought they had ends up being a disaster. In the ensuing paragraphs and pictures, we are going to expose a HUGE quality difference that you must consider when purchasing ANY performance part for your vehicle. Like the proverb says: "Let the Buyer Beware"...

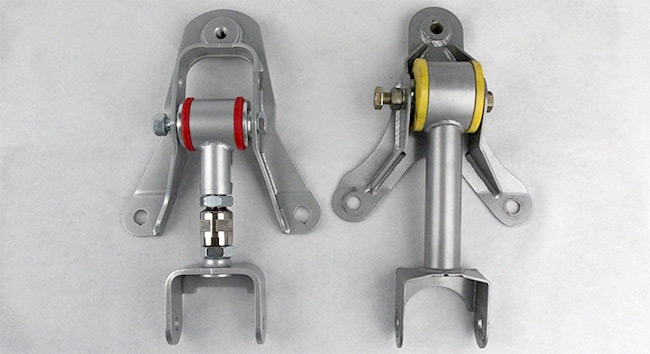

[caption id="attachment_2423" align="aligncenter" width="650"] Steeda Versus Brand X - Click to Supersize Image[/caption]

Steeda Versus Brand X - Click to Supersize Image[/caption]

To the average person there is probably little perceivable difference in the various suspension components that are available for a Mustang today. From an casual observation perspective, they share common mounting points - but there are an untold multitude of differences that are related to their inherent design, engineering, and materials used in fabrication that result in substantial handling, NVH (noise, vibration, and harshness), performances gains, and durability... Differences that you need to be aware of so as to maximize performance and ensure safe operation of your vehicle.

[caption id="attachment_2430" align="aligncenter" width="650"] On The Right,

Brand X's Super Thin Material is Failing Under Normal Use[/caption]

On The Right,

Brand X's Super Thin Material is Failing Under Normal Use[/caption]

The photo above compares the two different upper control arms for a 2005 - 2014 Ford Mustang. The upper control arm is a critical part of a Mustang's rear suspension - properly selected and installed it reduces wheel hop and improves traction under hard acceleration. The picture with the red bushing is our regular production upper control arm (#555-4112) with our upper chassis link (#555-4027) and the part with the yellow bushing is a typical competitive part from Brand X. To the casual observer, they look somewhat similar - but there are HUGE differences in how they are engineered, constructed and how they will hold up under demanding street and track use. For one, the Steeda part is fully adjustable, allowing you to dial in the appropriate pinion angle without removing the arm from the vehicle.

Welding

Note that the material on the Steeda part is painstakingly TIG welded in the optimum locations with the exact level of weld penetration and heat application for fusing the parts together - this ensures an exceptionally strong finished component structure. Additionally, the Steeda part is stitch-welded to ensure that no warping occurs during fabrication. Sure this takes more time and cost more to construct, but the end result is a solid finished product that is structurally sound and still true to engineering specifications.

[caption id="attachment_2419" align="aligncenter" width="650"] Superior TIG Steeda Welds[/caption]

Superior TIG Steeda Welds[/caption]

Note that the welds on the Brand X product have indication of less than ideal weld penetration with weld material sitting on top of the material, rather than being integrated and fusing the material together - this results in inferior strength and structural durability of the completed product as the weld lacked the heat to properly bond the parts together for maximum strength. Furthermore, the weld appearance is indicative of a quickened welding process where cost is the prime consideration verses strength. Remember, with any weld, it is the degree of weld penetration and fusion of metal that occurs that matters most - verses - the amount of weld material sitting on top of the parts being joined.

[caption id="attachment_2418" align="aligncenter" width="650"] Inferior MIG Brand X Welding[/caption]

Inferior MIG Brand X Welding[/caption]

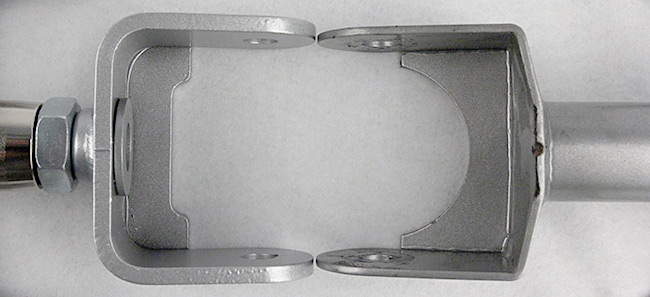

Material Strength

The Brand X product lacks the heavy-duty construction of the Steeda part, with material in some key areas less than 50% of the thickness of the same area on the Steeda part. In the photos below, the Steeda bracket has a dimensional thickness of 6.39mm and the Brand X dimension is a meager 3.21mm - with the tremendous forces this part is subjected to, it is only a matter of time before the part will flex, bend, and ultimately have a catastrophic failure when the vehicle launches exceptionally hard or is subjected to the tremendous forces of track and aggressive street driving.

[caption id="attachment_2421" align="aligncenter" width="650"] Brand X Uses Inferior, Thin Materials[/caption]

Brand X Uses Inferior, Thin Materials[/caption]

[caption id="attachment_2446" align="aligncenter" width="650"] Steeda's Materials are TWICE as Thick as

Brand X[/caption]

Steeda's Materials are TWICE as Thick as

Brand X[/caption]

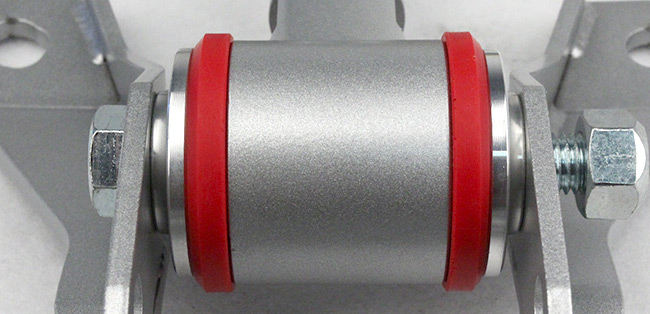

Bushings

From a busing perspective, the Brand X products synthetic bushing employs a pinhole voiding feature and lacks a thrust washer to properly retain the bushing within the structural housing. The construction technique results in reduced structural durability and integrity in the long-term and is prone to excessive NVH (Noise, Vibration, Harshness) characteristics as it wears because it lacks overall structural durability and integrity.

[caption id="attachment_2433" align="aligncenter" width="650"] Brand X Lacks Thrust

Washers, Inducing Unwanted Lateral Movement[/caption]

Brand X Lacks Thrust

Washers, Inducing Unwanted Lateral Movement[/caption]

The Steeda bushings we use in our upper control arm are a special proprietary three-piece design (see image below) we engineered and competition tested to enhance performance and reduce NVH over other inferior competitive designs. We strategically integrate a thrust washer to secure the bushing, further increasing structural integrity and providing reduced slop. Designed for demanding use on both the street and track, our part has been extensively tested on our race cars under the most severe conditions possible - all without failure and compromise!

[caption id="attachment_2435" align="aligncenter" width="650"] Steeda's Thrust Washers,

Eliminate Unwanted Lateral Movement[/caption]

Steeda's Thrust Washers,

Eliminate Unwanted Lateral Movement[/caption]

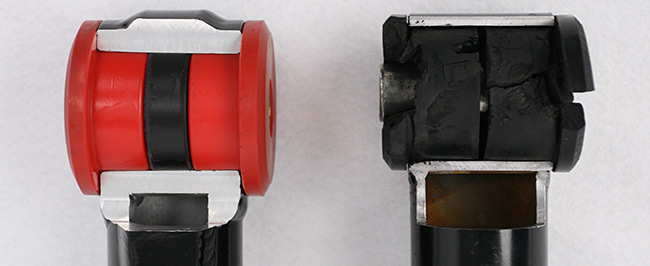

As an additional example of the vast hidden differences in control arms today, look at the cut-away photo below in which we expose the differences in a typical non-adjustable upper rear control arm for the 1979 - 2004 Mustang in the market today. The non-Steeda control arm in this picture was installed on a street Mustang and after installation, it quickly deteriorated to the point where there was a serious "slop" in the rear suspension as the bushing in the control arm suffered wear under the stress it is subjected to. Suffice to say, with this component part, the vehicles handling capabilities and the NVH characteristics diminished ever further as the bushing prematurely failed due to its design and construction.

In the picture below, you can see how we cutaway the upper control arms to expose exactly what went wrong for everyone to see. In this case, the durometer (the measure of the hardness of the bushing) was too stiff - and this stiffness caused dramatically increased noise, vibration, and harshness to be transferred to the vehicles chassis, and in addition, with the tremendous stress the control arm is subject to, premature wear of the busing occurred that resulted in adverse handling and essentially a failure of the suspension assembly.

[caption id="attachment_2440" align="aligncenter" width="650"] Steeda's Three Piece Bushing (left) Eliminates Bind Unlike Other Brands, Which are Known to

Fail[/caption]

Steeda's Three Piece Bushing (left) Eliminates Bind Unlike Other Brands, Which are Known to

Fail[/caption]

In this picture, you can see just how much more thought and engineering went into what we designed, engineered, and manufactured under our strict ISO 9001-2008 manufacturing processes. We specifically designed the control arm out of lightweight aluminum, and provided increased reinforcement in key critical areas where it is subjected to extreme stress. In addition, we employ an industry exclusive design of incorporating three busing materials into one - the outer bushings (red in color) have a specific durometer rating so as to limit NVH and provide the flexibility required for suspension movement, and the center bushing (black in color) has a much higher durometer rating so that it provides the tight travel and control a reduction in lateral movement that is desired for maximum control and traction.

In addition to the obvious differences in bushings, we purposely constructed this Steeda upper control arm out of 6061 aerospace grade aluminum alloy - an alloy that affords tremendous strength and one that also dramatically reduces the un-sprung weight of the suspension. TIG welded, our control arm in this instance is 25% lighter than the factory control arm and is less than one-third the weight of competitive steel control arms. Remember, un-sprung weight is "the enemy" when it comes to suspensions as it has a negative effect on how your suspension system reacts as it encounters uneven road surfaces and in addition, it results on harsher riding conditions as the increased mass is being moved around.

In summary - not all suspension components are created alike - there are major differences in engineering, manufacturing, and material quality. So - when you set out to enhance the performance of your vehicle, remember "The Steeda Difference".

Designed, Engineered, and manufactured under strict ISO 9001-2008 Standards and competition tested under the most grueling race conditions on the planet, the Steeda name is your GUARANTEE of quality. Made in the USA and with a lifetime guarantee - you simply cannot buy any better performance part.

Steeda - Speed Matters